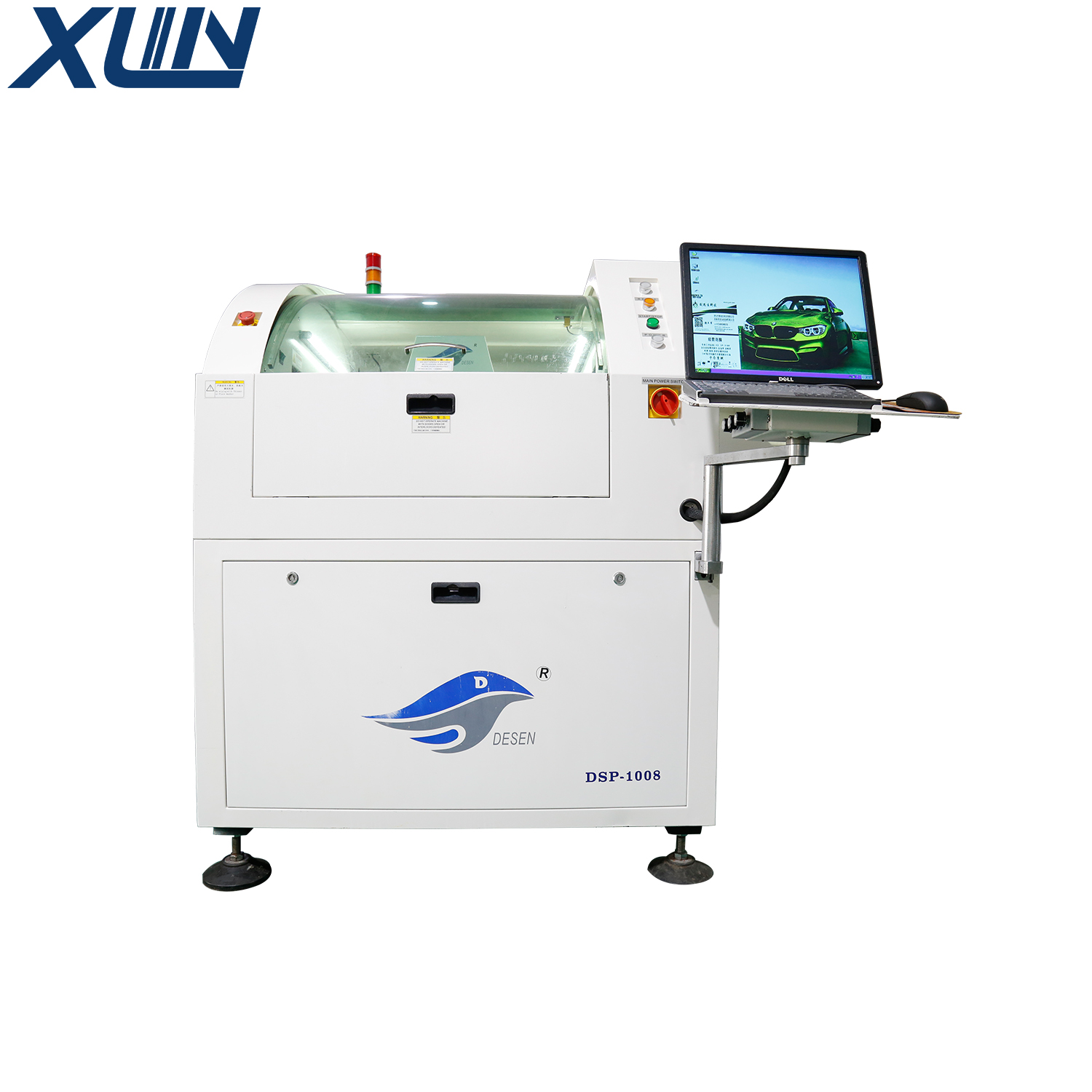

Ọsọ dị elu PCB SMT Solder Paste Printer PCB SMT Stencil Printer

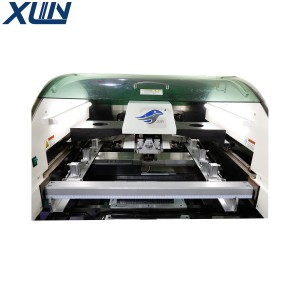

Igwe eji ebi akwụkwọ nke oge a na-ebufe efere efere, na-agbakwunye paste solder, embossing, nnyefe bọọdụ sekit na ihe ndị ọzọ. Ụkpụrụ ya na-arụ ọrụ bụ: buru ụzọ dozie bọọdụ sekit ka a ga-ebipụta na tebụl nbipụta, mgbe ahụ, n'aka ekpe na aka nri nke ngwa nbipute na-agbapụta mado solder ma ọ bụ gluu na-acha uhie uhie na mpempe akwụkwọ kwekọrọ na nchara nchara. PCB nwere mbipute na-efu efu bụ ntinye na nrụnye site na tebụl nnyefe maka nbanye akpaaka.

Usoro ọrụ nke ngwa nbipute SMT akpaka:

1. Lelee ma malite akụrụngwa tupu arụ ọrụ dịka usoro ọrụ si dị;

2. Debe PCB (mmezi PCB enweghị ike imezu ihe achọrọ nke mmepụta, a ga-agbakwunye efere na-akwado) na etiti ntinye;

3. Debe ihuenyo na mpempe akwụkwọ dịka ntụziaka nke akụ ihuenyo gosipụtara;

4. Họrọ mmemme mbipụta akwụkwọ kwekọrọ na ngwaahịa ndị a na-emepụta, tinye * * ọnọdụ maka nhazi ihuenyo, ma mebie ọnọdụ obibi akwụkwọ;

5. Mgbanwe mbipụta: gbanwee ọsọ obibi akwụkwọ, nrụgide na akụkụ iji mee ka ọnụ ọgụgụ nke tapawa solder ebipụtara na PCB mpe mpe akwa;

6. Ihe mbụ a ga-akwado site n'aka onye na-ahụ maka nkà na ụzụ na mmepụta ihe dị ukwuu ga-arụ ọrụ mgbe ọ ruru eru;

7. A ga-enyocha mbadamba 30 ọ bụla a na-ebipụta site na onye nyocha ma ziga ya na onye na-ebuli elu mgbe ọ gafesịrị nyocha ahụ;

8. Mgbe arụ ọrụ ahụ gasịrị, wepụ ihe mkpuchi ihuenyo ma hichaa ya, mechie ya dịka usoro ọrụ si dị, ma hichaa tebụl ọrụ.

Ihe achọrọ maka ngwa nbipute akpaaka SMT:

1. Yiri gloves rọba ma ọ bụ uwe mwụfu mgbe ị na-arụ ọrụ tapawa solder. Ọ bụrụ na a na-ejigide ihe na-ere ahịa na mberede na akpụkpọ ahụ, kpochaa ya ozugbo na mmanya na aka sanitizer, wee kpochaa ya na nnukwu mmiri;

2. A ga-agwọta tapawa nke fọdụrụ na-ere ahịa, mpempe akwụkwọ na-ehichapụ ihuenyo na uwe mwụda mgbe arụchara ọrụ ya dị ka usoro ndị dị mkpa nke ụkpụrụ gburugburu ebe obibi si dị;

3. Hichaa ngwá ọrụ, ngwá ọrụ na ngwá ọrụ tupu eji ya, karịsịa ṅaa ntị pụrụ iche na ọnọdụ nchebe gburugburu ebe obibi na saịtị tupu nhazi ngwaahịa na-enweghị ndu.

PCB Parameters

Ụdị DSP-1008

Oke bọọdụ kacha (X x Y) 400mm × 340mm

Opekempe osisi size 50mm × 50mm

PCB ọkpụrụkpụ 0.4-5mm

Akwụkwọ agha ≤1% diagonal

Oke bọọdụ dị arọ 0-3kg

Oghere dị n'akụkụ osisi 20mm

Ọsọ mbufe 1500mm/s(Max)

Nyefee elu site na ala 900± 40mm

Nyefee ntụziaka orbit akaekpe-aka nri, akanri-ekpe, akaekpe-ekpe, akanri- akanri

Ọnọdụ mbufe Otu ogbo orbit

PCB damping usoro Programmable mgbanwe n'akụkụ mgbali + Adaptive PCB osisi ọkpụrụkpụ + Edge mkpọchi isi mwekota(Nhọrọ: 1. Multipoint ele mmadụ anya n'ihu agụụ nke ala; 2. Edge kpochidoro na mkpụrụ clamping)

Usoro nkwado magnetik thimble, Equal high block, etc.(Nhọrọ: 1.Vacuum Chamber; 2.Special workpiece fixture)

Oke arụmọrụ

Nkwughachi nkenke nhazi onyonyo ±10.0μm @6 σ,Cpk ≥ 2.0

Nkwughachi nkenke nke mbipụta ± 20.0μm @6 σ,Cpk ≥ 2.0

Oge okirikiri<7s (wepu mbipụta na nhicha)

mgbanwe ngwaahịa<5 nkeji <br /> Oke onyonyo

Ugbo anya 8mm x 6mm

Ndozi nhazi ọkwa X:±5.0mm,Y:±7.0mm,θ:±2.0°

Ụdị ihe nrịbama ọkọlọtọ Standard shape benchmark point(SMEMA standard),solder pad/openings

Sistemu Igwefoto Igwefoto nọọrọ onwe ya, Sistemụ onyonyo onyonyo elu/ala

Oke obibi akwụkwọ

Isi obibi akwụkwọ na-ese n'elu isi obibi akwụkwọ nwere ọgụgụ isi (moto abụọ nwere onwe ha jikọtara ọnụ)

Template etiti nha 470mm x 370mm ~ 737 mm x 737 mm

Ebe obibi akwụkwọ kacha (X x Y) 450mm x 350mm

Squeegee ụdị ígwè scraper / gluu scraper (Angel 45 ° / 50 ° / 60 ° kenha na-ebi akwụkwọ usoro)

Squeegee ogologo 300mm (nhọrọ na ogologo 200mm-500mm)

squeegee elu 65± 1mm

Squeegee ọkpụrụkpụ 0.25mm diamond dị ka carbon mkpuchi

Ụdị mbipụta mbipụta otu ma ọ bụ okpukpu abụọ

Demoulding ogologo 0.02 mm - 12 mm

Ọsọ mbipụta 0 ~ 200 mm/s

Nrụgide mbipụta 0.5kg - 10Kg

Mbipụta strok ± 200 mm (Site na etiti)

Oke nhicha

Ọnọdụ nhicha 1. Usoro nhicha mmiri; 2. Ụdị nkụ, mmiri na agụụ

Ogologo ihicha na ihicha osisi 380mm (nhọrọ na 300mm, 450mm, 500mm)

Akụrụngwa

Ike chọrọ 220± 10%,60/60HZ-1 ¢

Mkpa ikuku chọrọ 4.5 ~ 6Kg / cm2

Akụkụ mpụga 1114mm(L)*1360mm(W)* 1500mm(H)